EnergyCuring News

EnergyCuring News

Exciting News: Our First Appearance at PaintIndia from February 19 – 21, 2026!

We are pleased to announce our first participation at PaintIndia, taking place in Mumbai from February 19–21, 2026.

This marks an important step as we expand our presence in the Indian market.

Meet our team at the booth: Gerald Grammig (Distribution Manager International Sales) together with our new Technical Sales Managers, Hitesh Mishra and Suresh Kharwar.

As a global supplier of UV, LED and EB curing raw materials, we support your formulation needs across inks, coatings, adhesives, 3D printing, electronics and many other specialized applications.

Location: Bombay Exhibition Center, Mumbai, India

We look forward to welcoming you in person, discussing current topics, exploring new opportunities, and further building our partnership.

Visit us at booth K05, Hall 04 - see you in Mumbai!

Visit us at Big Ideas in San Diego from March 2 -3, 2026

RAHN is excited to participate in Big Ideas in San Diego, an event bringing together innovators and industry leaders shaping the future of energy curable technologies.

Location: Aboard the historic USS Midway Aircraft Carrier & Museum in San Diego.

Meet our team on site to discuss new solutions, exchange insights, and explore opportunities for collaboration.

We look forward to seeing you in San Diego!

Unlocking the Power of Oligomers in UV/EB/LED Formulations

The foundation of high-performance energy-curing formulations lies in the smart selection of key components - oligomers, monomers, and photoinitiators. Among these, oligomers are the true game-changers, defining critical properties such as cure speed, film formation, flexibility, hardness, adhesion, and chemical resistance.

At RAHN, we’ve taken a deep dive into oligomer performance with our updated Oligomer Screening Lab Report. This comprehensive study benchmarks a wide range of oligomer types under consistent conditions, providing formulators with clear, reproducible insights into how each oligomer influences UV/EB/LED formulations across applications like coatings, inks, adhesives, 3D printing, and composites.

What’s Inside the Report?

Our screening approach evaluates key properties side by side:

- Reactivity – Cure speed under UV conditions

- Hardness & Flexibility – Balancing rigidity and elasticity

- Chemical Resistance – Durability against solvents

- Yellowing & Outdoor Durability – Long-term stability

- Viscosity – Processing and formulation ease

Key Highlights for Formulators

- GENOMER* 2263 & 2252 – Top performers for reactivity and hardness, ideal for scratch-resistant coatings.

- GENOMER* 4302 – Combines fast cure, hardness, and outdoor durability, perfect for demanding environments.

- GENOMER* 2253 – Delivers fast cure with flexibility, a rare combination for label inks and flexible coatings.

- GENOMER* 4281 – Strikes an exceptional balance between hardness and flexibility, reducing brittleness risks.

- GENOMER* 3414 – Low TG, but high reactivity and flexibility.

Our data-driven insights help you avoid common pitfalls like brittleness, yellowing, or poor surface cure - empowering you to tailor formulations for speed, durability, or flexibility.

Why This Matters

Not all urethane acrylates are soft and flexible. Not all epoxy acrylates are hard and brittle. Every oligomer has its own unique performance profile - and understanding these differences is the key to smarter formulations.

Download the full Oligomer Screening Lab Report now and discover how these insights can transform your formulation strategy.

German Ink Ordinance (GIO): Are You Ready for 2026?

The transition period is ending soon! Starting January 1, 2026, the German Ink Ordinance (21st Amendment to the Consumer Goods Ordinance) becomes legally binding.

What does this mean?

- Substances listed in the GIO’s positive list may be used in printing inks and coatings for food contact materials.

- Alternatively, non-listed substances may also be used but shall demonstrate a migration level of less than 10 parts per billion (ppb) and shall not exhibit carcinogenic, mutagenic, or reprotoxic (CMR) properties.

- Compliance with Swiss Ordinance or EU Framework Regulation (EC No. 1935/2004) will no longer be sufficient for the German market.

Key Implications:

- All food contact materials shall comply with GIO to access the German market.

- Existing formulations may need reformulation, migration testing, or substitution of non-compliant substances.

How RAHN can help: With years of regulatory expertise, we offer:

- Comprehensive compliance support on food contact legislation and other chemical legislation (e.g., REACH,…)

- Guidance on alternative raw materials

- Strategic planning to ensure a smooth transition

Recognition of Excellence: EcoVadis Gold Medal Award

We are pleased to announce that our organization has been awarded the EcoVadis Gold Medal, placing us among the top 5% of over 150,000 companies assessed globally. EcoVadis is a leading provider of business sustainability ratings, evaluating companies across 21 criteria within four key areas:

- Environmental Impact

- Labor and Human Rights

- Ethical Business Practices

- Sustainable Procurement

This distinction reflects our ongoing commitment to responsible business practices and our dedication to economic, environmental, and social sustainability. We are honored by this recognition and remain steadfast in our efforts to drive positive change across our operations and value chain.

Why UV/EB Curing Technology is a Game Changer in the Coil Coating Industry

The coil coating sector is rapidly adopting VOC-free UV/EB curing technology, thanks to advancements in resin performance and application methods.

The European Coil Coating Association - ECCA - hails UV/EB as a pivotal game changer for industry decarbonization, with leading manufacturers already making the switch.

Benefits of UV /EB Curing:

- Reduced Energy Consumption: lower operational costs and environmental impact

- Solvent-Free Formulation: promoting sustainability and reducing emissions

- Enhanced Material Efficiency: less waste and improved performance

Watch Our Latest Video: Discover how UV/EB curing technologies are transforming coil coating by enabling faster, greener, and more cost-effective production with excellent product performance.

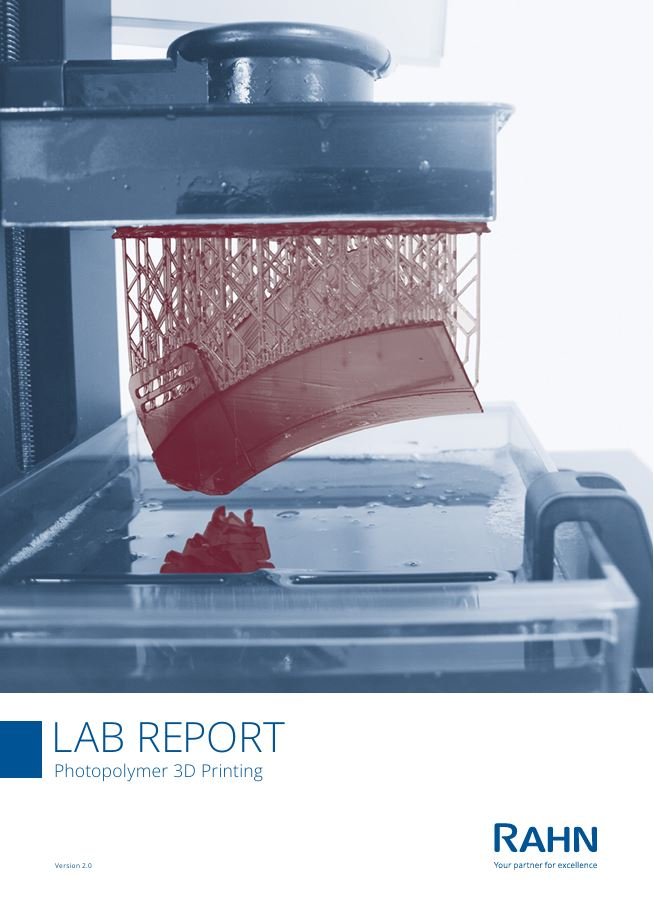

New 3D Printing Lab Report available!

Are you looking to elevate your 3D printing capabilities with high-performance materials engineered for precision and reliability?

Enhance your photopolymer 3D printing capabilities with RAHN’s advanced portfolio of materials, including oligomers, monomers, stabilizers, and photoinitiators. Designed to meet the rigorous demands of industries such as automotive, aerospace, medical, and wearables, RAHN’s solutions are tailored for optimal performance and printability.

This report provides:

- Expert product recommendations

- Starting formulations for elastic, tough, and high-strength applications

- Insights into enhancing material performance and processing efficiency

At RAHN, we bring global expertise and support for UV applications to the rapidly developing 3D printing market. Whatever your needs, we have proven materials with extensive technical experience and world class technical and regulatory support.

Check out our new 3D printing lab report which will provide crucial information to assist in choosing the proper materials for your photopolymer 3D Printing formulation

Your personal contact