Post processing

of 3D prints

Post processing

of 3D prints

Post processing of 3D prints: Best Practices for Photopolymers

In 3D printing using photopolymers (SLA, DLP, and LCD, inkjet, volumetric, etc.) post-processing is not a cosmetic afterthought – it's a functional necessity.

Photopolymer-based prints emerge from the printer in a chemically incomplete state. Without proper post-processing, these parts often fall short in mechanical stability, dimensional accuracy, thermal performance, and appearance.

Why Post-Processing Is Necessary

Surface Tackiness Due to Incomplete Cure:

Immediately after printing, photopolymer parts often exhibit surface tackiness, a result of uncured resin remnants. These residual materials, which include irritant liquids and unreacted photoinitiators, remain on or near the surface and must be properly removed and cured.

Water Sensitivity:

Uncured or partially cured photopolymer parts are also highly sensitive to moisture. Water can penetrate the surface, especially in parts with a loosely crosslinked network, leading to swelling, degradation, or long-term mechanical instability.

Visual and Functional Defects:

Photopolymer prints often require support structures, which leave visible scars on the surface after removal. These not only detract from visual quality but can also interfere with functional interfaces, such as sealing edges or mechanical fit zones.

Incomplete Network Formation:

Even though the printed part appears solid, the photopolymer network is not fully formed after initial exposure. Photopolymerization halts prematurely once vitrification occurs – a point at which the network becomes glassy, restricting the movement of remaining reactive species. These species become trapped in the matrix, limiting further curing unless post-processing is applied.

This results in:

- A plasticizing effect on the polymer network

- A lowered glass transition temperature (Tg)

- Reduced modulus (stiffness)

- Increased softness, which may be detrimental in rigid or precision parts

In other words, the printed object lacks full structural integrity until post-curing drives the network toward complete crosslinking.

The Role of Post-Processing

Post-processing isn't optional – it's the final stage in completing polymerization. It eliminates unreacted components, solidifies mechanical and thermal properties, and restores the part’s intended performance envelope. Only through disciplined post-processing can photopolymer parts meet their design requirements in real-world use.

Support Removal in SLA/DLP/LCD Printing

Support structures are essential in SLA 3D Printing, DLP, and LCD printing, especially for overhangs, bridges, and complex geometries. However, their removal is one of the most delicate and potentially damaging steps in post-processing. Without a careful approach, support removal can leave scars, deform soft features, or even cause breakage in thin-walled or detailed areas.

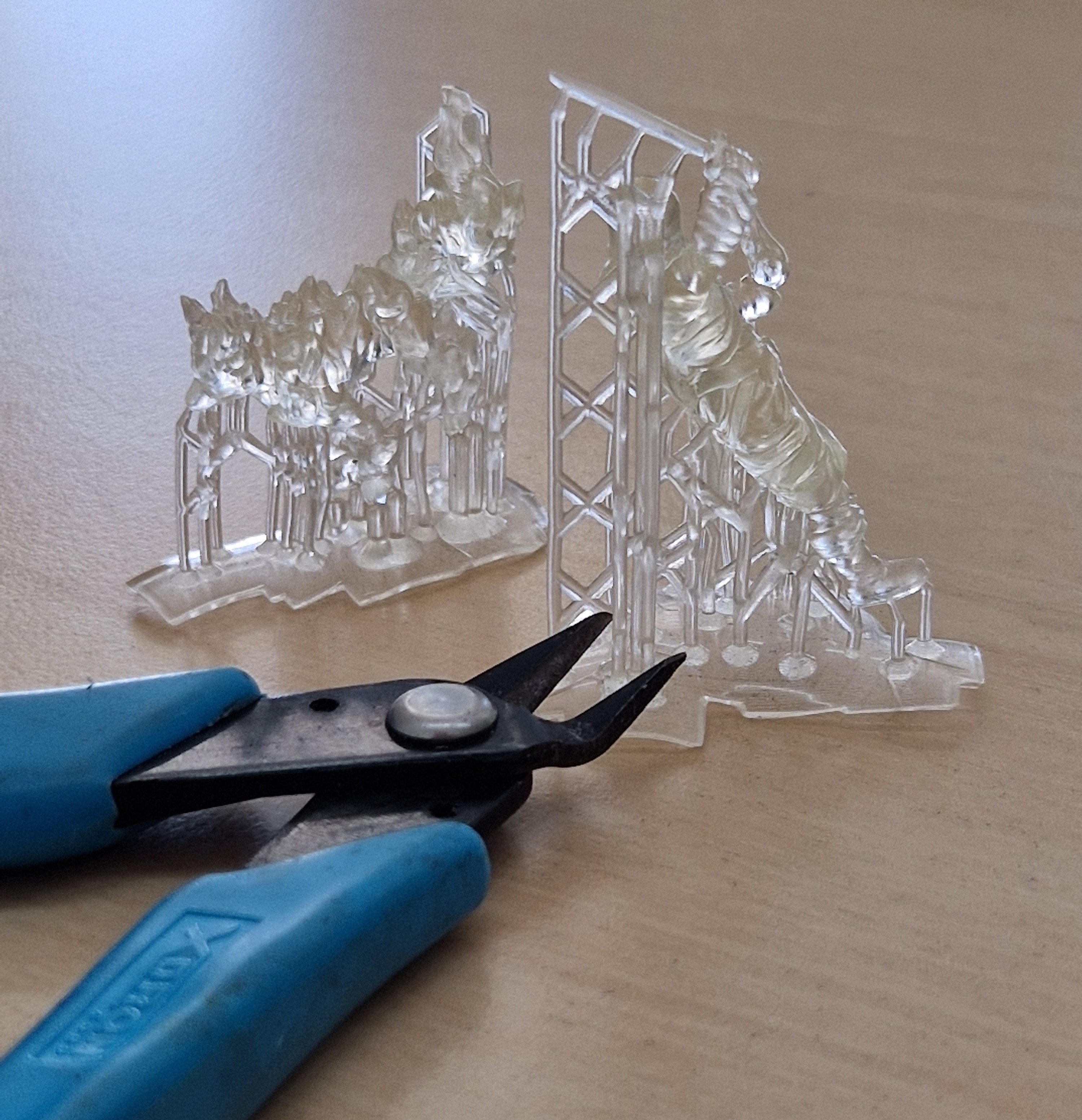

Manual Tools and Workflow Best Practices

The first line of defense in minimizing post-processing damage is using the right tools and following a consistent workflow.

- Flush cutters are the standard for removing support structures with minimal risk of tearing or gouging the cured resin. Their sharp, flat-edged blades allow users to cut supports as close to the part surface as possible without digging into it.

- Rinsing with isopropyl alcohol (IPA) is crucial immediately after printing and before or during support removal. IPA dissolves excess uncured resin, reduces tackiness, and makes the surface less prone to smearing or pulling when supports are detached.

- Performing a soft or partial post-cure before full support removal is a valuable technique to stabilize the part. A short initial UV exposure firms up the structure enough to handle, but keeps the resin slightly flexible, reducing the risk of chipping or tearing during support removal. The final full-strength cure can then be applied after supports are gone, ensuring complete polymerization.

Demonstration from our RadLab

Demonstration from our RadLab

Design Considerations: Orientation Matters

Support removal effort is heavily influenced by build orientation, which affects both the number and placement of supports.

Orienting the part to:

- Minimize support contact on visible or functional surfaces

- Reduce unsupported overhangs

- Allow easier access to supports for removal

…can significantly reduce post-processing time and improve the final surface finish. Strategic orientation decisions made during slicing directly impact how labor-intensive and clean the support removal process will be.

Surface Preparation and Finishing for Photopolymer Prints

After support removal and full post-curing, photopolymer parts often require additional finishing steps to improve surface quality, functionality, and visual appearance. This is especially true for end-use parts or presentation-quality prototypes where visible artifacts, roughness, or minor defects are unacceptable. Surface preparation for photopolymers follows a structured approach: mechanical refinement, surface leveling, and optionally, sealing or coating.

Sanding and Polishing:

Sanding is the primary method for mechanically refining photopolymer surfaces. It is essential that sanding and polishing be performed only after full post-cure, as uncured or partially cured parts remain soft, sticky, or dimensionally unstable. Sanding too early can distort delicate features or smear uncured resin across the surface.

This technique is best suited for rigid photopolymer resins with high modulus and thermal stability, such as GENOMER* 2297 and 2281, which respond well to fine abrasives. Sanding is typically used to:

- Remove support contact marks

- Smooth visible layer lines

- Prepare the surface for painting, coating, or sealing

Progressive sanding from coarse to fine grit followed by polishing compounds can achieve a near-gloss finish on flat areas of rigid parts.

Filling and Priming:

In cases where sanding alone cannot achieve a perfectly smooth finish – particularly in recessed or detailed regions – resin-compatible fillers or UV-curable surface solutions can be applied. These materials are formulated to bond well with photopolymer substrates and cure without interfering with downstream coatings or adhesives.

Filling and priming is commonly used to:

- Level out layer artifacts or shallow defects

- Blend support scar depressions into surrounding geometry

- Create a uniform surface prior to painting or spray coating

This step is often paired with sanding for high-smoothness applications, ensuring a clean base for finishing layers.

Brush or Spray Coating

Final coatings are applied for both functional and aesthetic reasons. Using a brush or spray, operators can apply clear or pigmented resins, epoxies, or sealants that:

- Improve water resistance (particularly important for parts used in humid or wet environments)

- Enhance visual appearance by adding gloss, matte, or color

- Reduce surface tack that may remain after post-cure

- Improve transparency by filling micro-defects and minimizing light scatter

These coatings work best when applied to fully cured, rigid, and well-prepared surfaces, often after sanding and priming. A clear epoxy topcoat, for example, not only smooths the surface but also protects the part from environmental exposure and mechanical wear.

Advanced Post-Curing for Photopolymers: A Lab-Based Perspective

Without post-curing, photopolymer parts remain underdeveloped in terms of mechanical integrity, dimensional stability, and thermal behavior. Proper post-cure is essential for achieving the full performance potential defined by the resin formulation.

Why Post-Curing Matters

Without post-curing, photopolymer parts remain underdeveloped in terms of mechanical integrity, dimensional stability, and thermal behavior.

Proper post-cure is essential for achieving the full performance potential defined by the resin formulation

Key enhancements resulting from proper post-curing include:

- Dimensional Stability – Reduces shrinkage over time and under stress

- Strength and Stiffness – Increases tensile and flexural performance

- Thermal Performance – Raises glass transition temperature (Tg) and heat deflection temperature (HDT)

- Water Resistance – Reduces moisture uptake in cured polymers

Post-curing is particularly important when the part must withstand mechanical loads, thermal cycling, or long-term exposure to moisture.

Key Lab-Based Findings

Extensive testing confirms that post-curing parameter – especially UV intensity, duration, and the inclusion of thermal curing – have a profound effect on the final properties of different photopolymer formulations.

Clear Impact Resin

- Flexural strength significantly improves between 15 and 60 minutes of UV curing.

- However, even at 60 minutes, the performance remains below the reference value, indicating that this resin requires optimized conditions for full mechanical development.

- Modulus increases over time, but still falls short of its potential without advanced curing methods.

Evolution of HDT and Impact Strength

RAHN’s starting point formulation (SPF) 1602 is a strong performer and exhibits dramatically better performance when UV curing is combined with thermal curing. The post-cure 4h at 405nm and 80°C (UV and temperature) resulted in:

- Lower color

- 100°C HDT B

- >25 KJ/m² unnotched impact strength from the use of GENOMER 4365

- UV-only conditions did not yield comparable results, highlighting the importance of dual-mode post-curing for this formulation.

These results demonstrate that not all resins respond equally to UV-only curing, and that resin-specific protocols are often required to meet performance targets.

Photoinitiator Optimization

Photoinitiator chemistry plays a central role in how a resin cures – both during printing and in post-curing.

- The use of advanced photoinitiator systems like GENOCURE CPK and GENOCURE MBF helps reduce surface tackiness and yellowing that can occur in sub-optimally cured parts.

- It's also essential to match the photoinitiator to the UV source used in both the printer and post-curing unit. For instance:

- 385 nm initiators are ideal for deep cure penetration

- 405 nm initiators are more common in desktop systems but may require longer exposure for full conversion

A mismatch between initiator chemistry and light source can result in incomplete crosslinking, poor surface quality, or long-term degradation.

Method Selection by Resin Type

Post-processing methods are not one-size-fits-all. The optimal approach depends heavily on the specific photopolymer formulation, its mechanical profile, and how it responds to UV and thermal post-curing. Resin classes, whether rigid, toughened, or elastomeric, each require different handling to preserve performance and avoid degradation.

Rigid Resins (e.g., GENOMER* 2297)

Rigid, high-modulus photopolymers like GENOMER* 2297 are well-suited to comprehensive post-curing, involving both UV exposure and thermal treatment. This dual-stage cure enables the material to reach its designed mechanical strength, stiffness, and thermal resistance.

These materials can tolerate and benefit from mechanical surface finishing techniques such as:

- Sanding and polishing

- Filling and priming

- Spray or brush coating

The rigidity and stability of these resins after full cure make them ideal for parts requiring precision surfaces, visual clarity, or durability under static load.

Flexible and Soft Resins

Elastomeric and 3D printing soft materials require more cautious handling during post-processing.

Instead of sanding or mechanical abrasion, sealing methods such as brush-on or spray coatings are preferred to protect the surface without compromising flexibility.

Maintaining the desired softness, rebound, and elongation requires careful balancing of cure time and intensity to avoid over-crosslinking.

Material-Specific Insights from Lab Testing / Starting Point Formulation (SPF)

RAHN’s lab results provide deeper insight into how specific resin types respond to post-curing strategies:

Elastomeric SPF V1

- Demonstrated higher rebound times at low post-curing time, indicating good elasticity retention. However, rebound times decreased with extended post-curing, highlighting the material's increased hardness. Additionally, longer post-curing improved the material's tear strength.

- However, improper curing could compromise this behavior, making controlled exposure essential.

Strong SPF V1

- The material demonstrated toughness in its green state, with high elongation at break. However, after thermal post-curing, its toughness significantly decreased, leading to increased brittleness, particularly after UV thermal aging. This highlights the risks associated with prolonged or overly intense curing in high-strength resins. Initially, the material appeared strong due to incomplete post-curing, but with proper, extended post-curing, it became brittle, indicating the need for reformulation. This is a common challenge with hard materials that have limited toughness.

- This behavior aligns with the material's limitations. The focus should be on optimizing the formulation rather than the post-curing process.

Tough SPF V1

- The material exhibits very low stiffness in its green state, characterized by a low modulus, which significantly increases with proper post-curing.

- While elongation slightly decreases, the material demonstrates higher strength, resulting in improved toughness and durability after proper post-curing. Additionally, there is no change observed after thermal aging, underscoring the material's durability.

- Showed a shift in the tan delta peak during dynamic mechanical analysis, a clear indicator of altered thermal behavior due to post-curing.

- This shift reflects changes in network mobility and glass transition, affecting how the part performs under load or heat.

- The material remains tough even after extended post-curing or thermal aging, indicating that the formulation is robust and the material is resilient to more intensive post-curing. The properties will change less in time compared to elastomeric SPF and strong SPF.

By understanding how each class of resin behaves during and after post-curing, users can select finishing techniques and curing protocols that align with the material's properties and performance goals. Tailored post-processing is key to maximizing function while minimizing unintended material changes.

Conclusion: SLA Prints Are Only Half-Finished at the Printer

Printing a part with SLA, DLP, or LCD technology is only the beginning of the photopolymer manufacturing process. What emerges from the build plate is not yet ready for functional use—it is chemically immature, dimensionally unstable, and mechanically underdeveloped. Only through proper post-processing does the part become a true representation of the resin’s intended performance.

The essential post-processing workflow follows a clear and deliberate progression:

Support Removal → Post-Cure → Surface Refinement → Optional Coatings

Each step builds on the previous one, transforming the raw print into a mechanically strong, thermally stable, and aesthetically finished part. Success with photopolymer prints depends heavily on:

- A formulation-specific curing strategy that matches the resin’s chemistry and design parameters

- Precise control of post-cure timing, temperature, and UV exposure

- The application of appropriate finishing techniques suited to the material class – whether rigid, flexible, or elastomeric

In short, post-processing is not optional. It is the stage where mechanical, thermal, and visual properties are fully developed, where printed geometry becomes a functional, reliable component.

Your personal contact